Project Description

Efacec invests 2.5 million euros in e-mobility

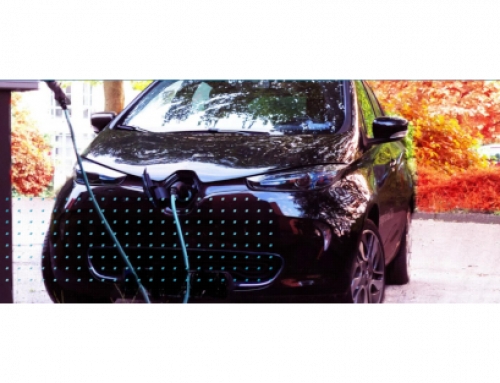

Efacec has inaugurated its new facilities dedicated to e-mobility with a total investment of €2.5 m. With this new plant, located in Maia, the company will increase its annual production capacity to 3,800 fast chargers, with the possibility of reaching up to 9,000 units, and plans to create more 340 jobs, related to new technologies and evolution patterns of mobility, by 2025.

To achieve a turnover growth of two to three digits annually in the next years, coming close to the €100 m barrier, is the objective of this strategic step.

The opening session was chaired by the Portuguese Minister of Economy, Manuel Caldeira Cabral, and was attended by Efacec’s majority shareholder, Isabel dos Santos, and guests from electric mobility, energy and R&D areas as well.

This new plant strengthens Efacec’s export capacity to demanding and sophisticated markets, namely United States of America and Europe. Currently the electric vehicle chargers developed by Efacec are present all over the world. Through its Electric Mobility unit, the Portuguese company produces a complete range of electric vehicle chargers for private, public, fast, ultra fast and wireless segments.

It should be noted that Efacec takes part on the main electric mobility projects worldwide, namely in the European consortium led by automotive OEMs, which will install 400 large power charging stations on the main roads in Europe, and as well on a similar project developed in the United States of America, which will invest $2 b over the next 10 years in charging infrastructure.

Pioneer in the area of e-mobility and a world leader in the production of fast and ultra fast chargers for electric vehicles, Efacec materializes in this new plant its continuous effort on R&D and product engineering. This infrastructure, which incorporates the best practices from the technology and engineering domains, has been designed looking for a large scale production of fast charging devices.

Prepared to take advantage from a strong support of IT tools to the production process, the plant has different operational areas, namely R&D laboratories, dedicated areas for product engineering and final test and 3D printing for quick prototyping. The entire process is based on the Lean Manufacturing concept, seeking to continuously optimize layouts and work sequences and monitoring, control, efficiency and quality methodologies as well.

See more: